ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

learn moreClear, complete centerline documentation for each and every product that will run on a production line is critical to ensure repeatable line performance. Centerline documentation should include optimum machine speeds, required changeover settings, and conveyor line speeds and settings. This documentation is required for every machine in the line, not just a few selected line components.

This sounds like common sense, but in practice, many vendors provide manuals for each machine in a line and walk away. Those manuals are fine for generally operating and maintaining a machine, but they do not address the fact that in an integrated line, precise machine + conveyor speeds and settings are required for each and every container to deliver smooth, steady-state operation.

Lack of such documentation refers to the mistake made when a vendor closes a project and the customer accepts the line without receiving a complete, detailed and accurate documentation package.

This mistake includes assuming that having manuals for every machine in the line is sufficient.

Experience has taught us that machine manuals and related production equipment documentation are just the start.

Symptoms: What happens when documentation for the complete production line including optimum machine centerlines and line settings and are not provided by the vendor?

When essential documentation is missing, operators and maintenance personnel start guessing and tinkering with machine settings in an attempt to make improvements. Without documented benchmarks, changing critical machine and line settings can lead to even worse line performance.

Since optimum line centerlines are typically established during startup, machine vendors may likely not have a record of the final settings. Documenting all changeable settings, including HMI variables, is critical to ensuring repeatable line performance in the future.

How do we avoid making this deadly mistake?

We protect customers from the problems caused by these mistakes by creating and providing complete system documentation, including all physical changeover points, machine settings and changeable HMI settings prior to hand-off.

Typically this documentation is also used in training programs for controls engineers, operators and maintenance personnel.

We provide the following library of documentation as part of every turn-key project:

- Physical container changeover settings for each product size

- HMI Recipe settings per product size

- Non-recipe, HMI changeable variables

- Every production line variable for every product size including conveyor speeds, line control sensor time delays and sensor placements

Our packaging line documentation is structured so that it can easily be printed, laminated and posted at each machine for quick, convenient access.

If you are working with another vendor on a packaging line design project, or if you are currently evaluating potential vendors, we encourage you to ask them about the documentation they provide.

And make sure to ask for examples.

To learn more about the Deadly Mistake of Lack Of Documented Machine Centerlines & Line Control Settings and how we protect our customers from it, please e-mail us at [email protected].

Preventing unnecessary machine and line control adjustments, or helping make certain they are quickly flagged and resolved, is essential to steady-state line operation.

Occasionally production line personnel make changes to machine speeds, conveyor speeds, torque settings, time delays, or sensor placements without truly understanding the impact of those changes on overall line performance.

In many cases, these changes result in unintended negative consequences. Those unintended consequences almost always negatively impact line OEE.

Thoroughly understanding line and equipment integration interdependencies is essential to avoiding this mistake.

Unnecessary Machine & Line Controls Adjustments refers to the mistakes of:

- Failing to adequately train operators on the importance of established machine and line settings

- Failure to train personnel on the consequences of out-of-standard machine adjustments

- Failure to display established machine and line settings in prominent locations

- Allowing operators to access machine control settings that they don’t need to access

- Failing to immediately alert the plant floor that out-of-specification adjustments have been made to a machine or the line controls

Symptoms: What happens when unnecessary adjustments are made to machine and line control settings?

The most common negative OEE impacts are likely to be:

- Starved machines

- Blocked machines

- Chronic start-stop-start line operation

- Chronic ramp-up, ramp-down, ramp-up cycling

- Below target production speeds

- Down containers

- Container jams

Each of these impacts create downtime, slow down the line, and prevent steady-state operation. This translates into reduced productivity, lost revenue, higher labor costs and a longer than planned return on your investment.

ZARPAC works closely with customers to help protect them from this Deadly Mistake.

Examples of effective approaches include:

- Visible and audible alarms when machine setting(s) are out of range – Alarms alert line leads or shift managers to the change so they can address the issue. Alarms have the added benefit of shining the spotlight on repeat offenders which in many cases has the potential to discourage this behavior.

- Password protected HMI screens, settings or buttons – Operators need access to very specific machine settings to operate a machine. Many customers choose to prevent operator access to any non-essential functions.

- Prominently displayed, complete machine settings – Simple, easy to read signage at each machine and at the line controls station are essential.

- Training, training, training – Training should address more than how to operate a machine. It should also address how each machine fits into the overall line, and why the standard settings are the optimum settings, and what happens when someone changes them.

- Production line monitoring, data collection and reporting systems – ZARPAC is serious about measuring, monitoring and optimizing production line performance. That is why ZPI Monitor & Report is now included in all ZARPAC line integration projects. Monitor & Report captures, aggregates and stores every signal from every piece of equipment in a production line, from inbound raw material handling to palletized finished product. If something happens on a machine anywhere in a production line, the system captures it and customers can analyze it. It can quickly identify what was changed, when it was changed, and what happened as a result of the change.

While we cannot guarantee that this Deadly Mistake will never occur, we can guarantee that we will work closely with every customer to help prevent it, and to help mitigate the impact when it does occur.

To learn more about the Deadly Mistake of Unnecessary Machine & Line Control Adjustments and how we work with customers to address it, please e-mail us at [email protected].

When a vendor fails to invest in helping a customer fully understand a new production line and then walks away after hand-off, the customer is left with big problems waiting to happen.

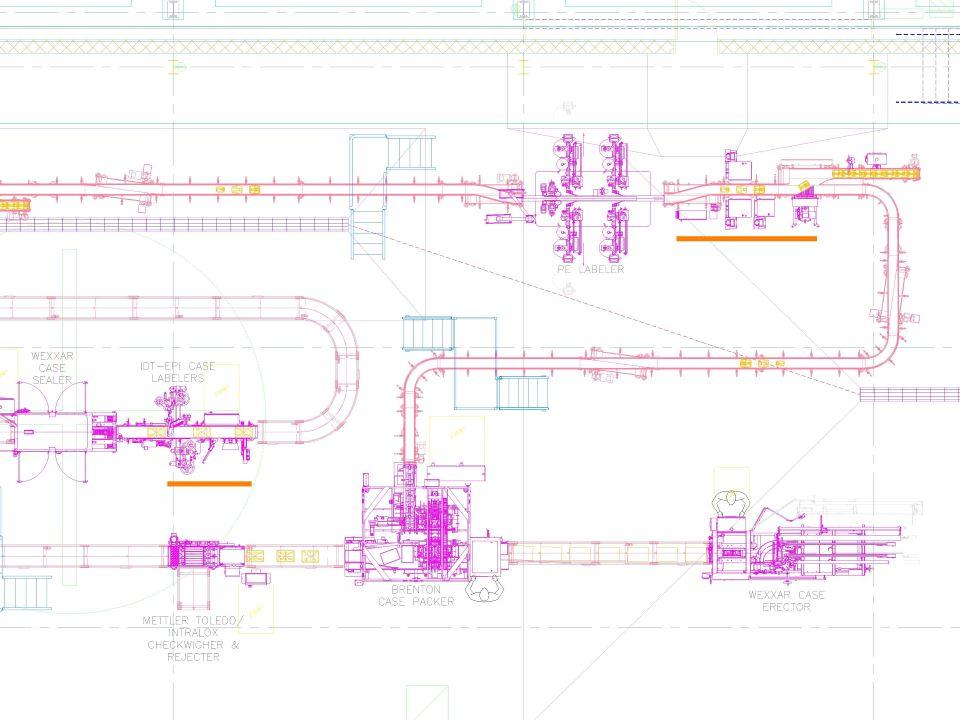

Packaging lines are extremely complex systems that when correctly designed and integrated operate smoothly at rated speeds.

Within each line there are hundreds, if not thousands of inter-relationships that are not immediately obvious and may not be fully understood.

Inadequate customer understanding of the line design at hand-off refers to:

- Insufficient customer understanding of why the line is designed the way it is designed

- Insufficient customer understanding of the interrelationships of all machine, accumulation and conveyor speeds and line settings

- Lack of customer understanding of what happens when out of specification adjustments are made to machine and line settings

What bad happens when the customer does not fully understand a packaging line at hand-off?

Typically, machine speeds, sensor locations, conveyor controls…you name it, get changed or tweaked. This happens gradually at first but then accelerates as the impacts of each change are compounded, eventually resulting in major line operation issues.

The difficulty of troubleshooting such situations increases exponentially as recommended design settings get replaced by well meaning, but problematic settings. The line ultimately becomes a poster child for The Law of Unintended Consequences.

The most common negative OEE impacts are likely to be:

- Starved machines

- Blocked machines

- Chronic start-stop-start line operation

- Chronic ramp-up, ramp-down, ramp-up cycling

- Below target production speeds

- Down containers

- Container jams

Each of these impacts create downtime, slow down the line, and prevent steady-state operation. This translates into reduced productivity, lost revenue, higher labor costs and a longer than planned return on your investment.

ZARPAC works closely with customers to help protect them from the Deadly Mistake of Inadequate Customer Understanding Of Line Design & Integration At Hand-off.

Examples of effective approaches include:

- Training, training and more training for personnel with the capacity and motivation to assume the role of Line Champion(s).

- To us, a line champion is someone that understands the line the way our engineers and project managers understand the line. If we know it, we will share it as part of the training program.

- Training programs, including line champion training, are closely tied to packaging line documentation provided by ZARPAC.

- We have also developed and provided tiered training programs targeted for different personnel within the organization.

To learn more about the deadly mistakes of packaging line design and integration, and how we will help you avoid them, please e-mail us at [email protected].

Zarpac's turnkey design and management services are ideal for multiple applications: